Epoxy coatings are becoming increasingly popular for concrete surfaces due to their durability and ability to withstand harsh conditions. But, if you’ve already sealed your concrete surface, you may wonder if applying an epoxy coating over it is possible.

While sealing can help prevent future damage, it may create adhesion issues for the epoxy coating. With proper surface preparation, epoxy coatings are compatible with sealed concrete. You also need the actual procedure of how to epoxy over sealed concrete.

Let’s explain how epoxy coatings work on sealed concrete surfaces and how to prepare for a successful application. So, if you’re considering an epoxy coating for your sealed concrete surface, read on for essential information and expert advice.

How Can You Epoxy Over Sealed Concrete?

If you’re looking for a cost-effective way to upgrade your sealed concrete floors or other surfaces, epoxy coating is definitely worth considering. A few additional steps are needed in this case:

- Step 01: Preparing the surface for epoxy application

- Step 02: Choosing the right type of epoxy for your project

- Step 03: Using a primer for improved adhesion

- Step 04: Applying the epoxy coating

- Step 05: Curing the epoxy coating

Step 01: Preparing The Surface For Epoxy Application

Before beginning to apply any new coating, it is essential to remove the existing sealer on the concrete surface completely. This can be achieved through the use of a chemical stripper or mechanical grinding.

Neglecting to remove the previous sealer can result in poor adhesion, which may cause peeling or flaking of the fresh epoxy coat.

It is still important to use proper surface preparation techniques, such as cleaning and profiling, because the concrete was previously sealed. The adhesion and durability of an epoxy coating can be compromised if all contaminants and debris are not removed from the surface.

Despite misconceptions suggesting otherwise, filling in cracks and pits on sealed concrete surfaces with epoxy is possible. With the implementation of the necessary precautions prior to application, epoxy can effectively bond with sealed concrete, enhancing its durability and longevity.

Step 02: Choosing The Right Type Of Epoxy For Your Project

Choosing the right type of epoxy is critical to the success of your project. It can make all the difference, providing excellent adhesion and durability to surfaces such as concrete.

With numerous epoxies available, selecting one compatible with sealed concrete can seem daunting. But fear not. There are several factors to consider:

To begin with, check the compatibility of the epoxy with the sealed concrete surface. Next, ensure the surface is clean and free from contaminants before applying the coating. You should also inspect for cracks or damages that may require repair.

When selecting epoxy, it’s also essential to consider its ability to withstand environmental conditions and traffic loads specific to your application. Epoxies come in different formulations designed based on their exposure to chemicals, UV rays, heat and abrasion resistance, and impact resistance.

Step 03: Using a Primer for Improved Adhesion

Using a primer is an ideal way to enhance the adhesion between epoxy coatings and sealed concrete surfaces.

Primers work as a link between the two materials precisely by entering deep into the concrete pores, offering a rough surface for mechanical bonding. This provides long-term durability and performance for your newly coated floors.

By controlling water vapor transmission, primers prevent air bubbles from forming during the process on porous substrates such as concrete. Therefore, using a primer is an additional and suitable step to prepare your floors for epoxy coating.

Step 04: Applying The Epoxy Coating

Before applying the epoxy coating over sealed concrete, mix the two components according to the manufacturer’s instructions and follow safety precautions.

Epoxy coatings can come in various colors and textures, which makes them highly customizable to individual preferences. They can be blended with different aggregates to create a textured finish that mimics natural stone.

Cut in along the edges and walls using a brush before rolling out the rest of the floor. Consider factors such as humidity levels and slip resistance to achieve optimal results.

Multiple coats of epoxy can significantly improve durability by creating a thicker barrier between the surface and potential abrasions. Applying different colors for each layer enhances the finished product’s visual depth and complexity.

Following proper application techniques throughout the process is important to prevent bubbling, cracking, or peeling. Measure the mixture’s components accurately, mix them evenly, and apply them in thin layers. Allow ample time for curing between applications for the best results.

Step 05: Curing The Epoxy Coating

After application, curing takes between 24 to 72 hours, depending on factors such as temperature and humidity levels. Wait until the epoxy has fully cured before using it heavily or exposing it to traffic.

Some tips to remember during the curing process are:

- Avoid walking on newly applied epoxy coatings

- Do not place anything on top of a freshly coated surface

- Ensure proper ventilation in the area where the coating was applied

What Are the Benefits of Epoxy Coatings Over Sealed Concrete?

It all depends on the condition and type of sealant used. But, in general, epoxy coatings work great on sealed concrete surfaces in good condition, providing numerous benefits.

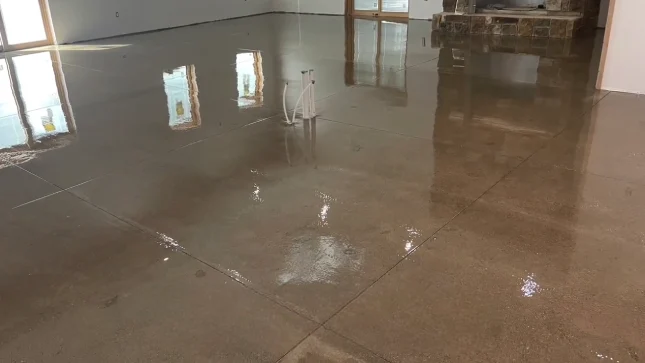

Epoxy coatings enhance the appearance of the floor with a glossy finish that reflects light, making the space brighter and more appealing.

Also, epoxy coatings form a durable barrier against wear and tear from foot traffic and heavy machinery movement. And they also protect against spills, stains, and other harsh chemicals such as oil, grease, and acids.

Can I remove the epoxy coating if I change my mind or want to refinish the surface?

Although epoxy coatings are durable and long-lasting, there may come a time when you need to remove them from your sealed concrete surface. Fortunately, epoxy coatings can be removed using several methods, including grinding, chemical stripping, or epoxy removers.

- Grinding is the most straightforward method, in which the surface is mechanically ground down to remove the coating.

- Chemical stripping involves using chemicals to soften and dissolve the epoxy, allowing it to be easily removed.

- Epoxy removers are specifically formulated products that are designed to break down the epoxy coating without damaging the underlying surface.

Note that epoxy removal is a labor-intensive and time-consuming process, so it is recommended to seek professional assistance.

How to maintain the epoxy coating over sealed concrete?

Maintaining the durability and appearance of an epoxy-coated concrete surface is essential. To accomplish this, keeping the surface clean, dry, and free of debris is crucial. Cleaning the surface regularly helps prevent the buildup of dirt, dust, or other particles that can eventually result in scratches or damage.

You should avoid using harsh chemicals like bleach or acids when cleaning the epoxy-coated surface, as these can cause discoloration or softening over time. Instead, opt for mild detergents mixed with warm water.

For removing stubborn stains like oil spills, grease marks, or tire tracks, specialized cleaners explicitly designed for epoxy coatings are available.

Inspecting the epoxy coating regularly for signs of wear and tear, such as chips, cracks, bubbles or peeling areas, is also crucial. Addressing these issues promptly can extend the floor’s lifespan and save costs on expensive repairs later on.

Which is better: concrete sealer or epoxy, for sealed concrete?

You should consider the area’s intended use when deciding between a concrete sealer and epoxy coating for your sealed concrete surface.

Concrete sealers are a budget-friendly option that provides protection against water damage and staining. Nevertheless, they are susceptible to wear and tear and may not hold up well against chemicals, oil, or grease.

On the other hand, epoxy coatings are durable and can withstand heavy foot and vehicle traffic. They provide an impermeable barrier against chemical damage and are also available in a variety of decorative designs.

Epoxy coatings apply to new and old concrete surfaces and can last years with proper maintenance.

So, if you require enhanced protection and durability for your sealed concrete surface, epoxy coating is the best option. But, if budget is a concern and your surface is not subject to heavy traffic or chemical damage, then a concrete sealer may be sufficient.

Revitalize Your Sealed Concrete with Long-Lasting Epoxy Coatings

Epoxy coatings are an excellent choice for achieving a polished, durable surface over sealed concrete. One of the significant advantages of using epoxy is its ability to resist chemicals and stains, making it ideal for garages and industrial settings.

Applying the appropriate type of epoxy, such as solvent-based or water-based, is crucial in achieving the desired results. Also, proper application techniques, including multiple coats and adding color or texture, contribute to its longevity and aesthetic appeal.

An epoxy-coated surface protects against wear and tear when adequately maintained through regular cleaning, extending its lifespan. In other words, epoxy coatings are your best option to seal concrete surfaces and achieve a glossy, attractive finish.