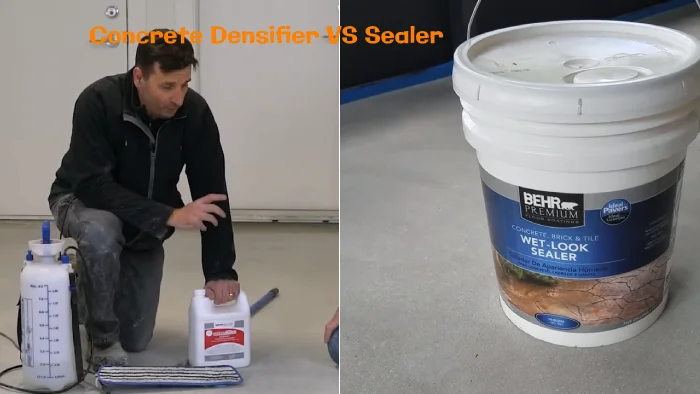

Concrete densifiers and sealers protect concrete surfaces from water penetration, abrasion, and chemical exposure. Although their purpose is similar, each has unique qualities that distinguish them.

The main difference between a concrete densifier and a sealer is that the concrete densifier penetrates into the pores of the concrete floor and reacts with them. In turn, this strengthens the wear and tear resistance.

Meanwhile, a concrete sealer forms a protective barrier on the surface of the concrete, preventing moisture, stains, and other contaminants from penetrating the surface.

Let’s explore the nuances of concrete densifiers versus sealers with greater depth so you will know when to use what.

Concrete Densifier Vs Sealer: Understanding the Key Differences

Let’s break down the distinction between the concrete densifier and sealer. Dive in and find out all the differences.

1. Purpose

Concrete densifiers are designed to penetrate and react with the concrete, creating a chemical reaction that fills the pores and creates a harder, more durable surface.

This process makes the concrete less permeable and more resistant to damage from water, chemicals, and other substances.

The densification process also reduces dusting and increases the surface’s abrasion resistance, making it more suitable for high-traffic areas.

On the other hand, sealers are designed to form a protective barrier on the concrete surface. This prevents water, chemicals, and other substances from penetrating the surface and causing damage.

2. Type

Various types of concrete densifiers are available, including sodium silicate, potassium silicate, lithium silicate, and colloidal silica. Each type has its unique characteristics and is suitable for different types of concrete surfaces.

For instance, sodium silicate is the oldest and cheapest type of densifier but unsuitable for decorative concrete.

Potassium silicate works well on highly porous concrete floors and is best mixed with lithium silicate for better bonding and higher strength.

Lithium silicate has smaller particles and gives higher penetration in harder concrete slabs, while colloidal silica has the smallest particles and reacts better with concrete with admixtures like pozzolan.

Similarly, there are different types of concrete sealers, including acrylic, polyurethane, epoxy coating, and polyaspartic. Each sealer type has unique properties, making it suitable for different applications.

For example, the acrylic sealer is the most affordable and easy to apply, but it does not offer the same level of protection as other sealers.

A polyurethane sealer is strong and chemical-resistant, so it’s great for industrial and commercial use.

Epoxy coating is suitable for high-traffic areas and offers excellent resistance to abrasion and chemicals. Polyaspartic is fast-curing and easy to apply, making it an excellent choice for time-sensitive projects.

3. Chemical Composition

Densifiers are typically water-based and contain chemicals that react with the concrete to fill its pores. These chemicals usually include sodium, potassium, or lithium silicates.

Sodium silicates penetrate deep into the concrete and react with the calcium hydroxide to form a stronger, more impermeable surface.

On the other hand, potassium silicates offer better resistance to abrasion, making them ideal for high-traffic areas. Lithium silicates, meanwhile, are favored for their ability to create a denser surface with increased resistance to water and stains.

Conversely, concrete sealers comprise various chemicals, including acrylic resins, epoxy or polyurethane systems, silane, silicates, lithium silicates, and siloxane.

Acrylic resins are commonly used for their ability to form a protective film over the surface of the concrete, providing good resistance to water, chemicals, and UV rays.

Epoxy or polyurethane systems, meanwhile, offer superior durability and resistance to abrasions, making them ideal for use in high-traffic areas or industrial facilities.

Silane and siloxane sealers penetrate deep into the concrete and form a chemical bond with the substrate, creating a water-repellent surface.

Like their densifier counterparts, lithium silicates are valued for creating denser surfaces that are more resistant to water and stains.

4. Appearance

While densifiers do not change the appearance of the concrete, sealers can enhance the color or gloss of the surface.

Sealers are available in various finishes, ranging from matte to high gloss, and can impart a wet look, which can be especially appealing for outdoor areas such as pool decks. Also, sealers can protect the concrete from damage caused by UV rays, water, and chemicals.

5. Shelf Life

When comparing concrete densifiers and sealers, it is important to note that the densifier has a significantly longer shelf life and does not require reapplication.

This is because densifiers penetrate deeper into the concrete, reacting with the calcium hydroxide to create a denser and harder surface.

In contrast, sealers only coat the surface of the concrete, creating a protective layer against water and stains.

6. Wear and Tear

In addition to their shelf life, another important factor to consider when comparing concrete densifiers and sealers is their wear and tear.

Sealer creates a layer on top of the concrete surface, which can wear down and chip away over time.

On the other hand, a densifier fills in the pores of the concrete, increasing its density and making it more resistant to wear.

Does concrete sealer make the surface slippery?

If the sealer is of low quality or has a high solid content, it can create a slick surface that is hazardous to walk on, especially when wet.

Choosing a sealer specifically designed to provide a non-slip surface is essential to prevent a slippery surface.

Some sealers contain additives that create a textured surface, making them more slip-resistant. Also, it’s important to apply the sealer correctly, following the manufacturer’s instructions carefully.

What should you do to get a quality concrete sealer for your needs?

When searching for a quality concrete sealer, it’s imperative to consider various factors such as surface type, environmental exposure, and required level of protection. Also, perusing expert and customer reviews can prove advantageous in making an informed choice.

As a starting point, you can check out our review of the epoxy concrete sealer, where we detailly reviewed some of the best quality epoxy concrete sealers, so you can find a top-rated epoxy concrete sealer that suits your needs.

How deep do concrete densifiers and sealers penetrate?

Concrete densifiers can penetrate the pores of a concrete surface from a few millimeters to a couple of centimeters. This depends on the type of silicate, concrete density, and amount of water in the capillaries.

The concrete densifier reacts with the free lime in the concrete to form a denser, harder surface that is less porous and more durable.

Sealers can penetrate as little as 1 inch into a dense concrete surface and up to 6 inches into porous surfaces.

This indicates that the depth of penetration of sealers is higher than that of concrete densifiers and depends on the porosity of the concrete surface.

Maintain Your Concrete Surfaces with Concrete Densifiers and Sealers: Choose Wisely

Understanding the differences between concrete densifiers and sealers is crucial for anyone who wants to maintain their concrete surfaces effectively.

While densifiers penetrate deep into the concrete surface to strengthen it and reduce porosity, sealers create a protective layer to prevent water, stains, and other contaminants from penetrating it.

When choosing between the two, it is essential to consider the intended use of the concrete surface and select the right product that meets your needs. Selecting a high-quality concrete sealer that does not make the surface slippery, is durable, and is easy to apply is also vital.

Considering these factors, you can ensure that your concrete surfaces remain strong, durable, and aesthetic for an extended period, saving you time and money in the long run.