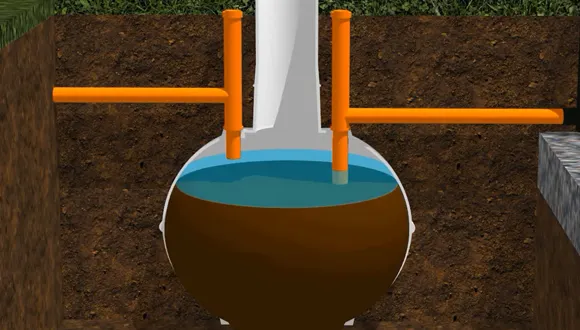

Having a functioning septic system is vital, and a properly sealed pipe is an important part of that. Over time, pipes can shift and settle, causing cracks and leaks. Sealing a pipe that passes through the concrete of a septic tank can be done with the right supplies and a little know-how.

Through this blog post, we’ll guide you on how to seal a pipe through a concrete septic tank. We’ll include what supplies you need and detailed instructions so you can get the job done right without causing any destruction.

How to Seal a Pipe Through Concrete Septic

Below are the steps that should be taken when sealing a pipe between concrete septic tanks:

Supplies Needed:

- Concrete sealant

- Caulking gun

- Safety goggles

- Dust mask

- Putty knife

- Old rags

- Teflon tape

Ensure Your Safety

When working with concrete, it’s essential to take precautions to protect your lungs from harmful particles. First, put on a pair of safety goggles to shield your eyes. Then, put on a rubber glove and dust mask to filter the air you’re breathing. Also, ensure you’re working in a well-ventilated area. Once you’ve taken these precautions, you’re ready to go for the next steps.

Inhaling too much concrete dust can lead to several health problems, such as coughing, wheezing, and difficulty breathing. It can also irritate your nose and throat and cause inflammation of your lungs. See a doctor as soon as possible if you experience any of these symptoms. With proper precautions, you can avoid these problems and stay safe while working with concrete.

Cut Off The Nozzle to Seal

Before applying concrete sealant, you will need to cut the nozzle of the tube at a 45-degree angle with a utility knife. Next, insert the tube into a caulk gun. To dispense the sealant, simply squeeze the trigger of the gun. Start by applying a bead of sealant along the crack or joint that you wish to fill.

Once you have applied an even bead of sealant, use a putty knife or your finger to smooth it out and ensure that it is level with the surface. To get a professional-looking finish, be sure to wipe away any excess sealant before it has a chance to harden. With just a little bit of effort, you can easily apply concrete sealant like a pro.

Smooth The Bead

After applying concrete sealant around the pipe, use an old rag to smooth out the bead of sealant. Make sure to go over the entire area where the sealant was applied and check for any gaps or air bubbles. Once you’re satisfied that the sealant has been evenly applied, wipe away any excess before it dries.

It’s best to apply a thin layer of sealant rather than trying to fill in large gaps. If you’re concerned about preventing water damage, consider using a waterproof sealant or tape around the edges of the pipe. These simple precautions will ensure that your pipes will stay in good condition for years to come.

Allow the Sealant to Dry

Once the concrete sealant has been applied around the pipe, it is important to let it dry for at least 24 hours before using the pipe again. This will give the sealant time to properly cure and create a strong bond with the concrete.

It is important to avoid exposing the sealant to water during this time, as this weakens the bond and causes the sealant to fail. By following these simple instructions, you can be sure that your concrete repair will be durable and long-lasting.

Wrap Teflon Tape

Once dry, wrap Teflon tape around male threads before screwing on a female fitting (or vice versa). This will create an additional watertight seal. Teflon tape is a type of plastic film that is coated with fluoropolymer resin. When applied to threads, it helps to create a smoother surface and prevent leakage.

It is important to wrap the tape in the same direction as the thread so that it does not become tangled. Once you have applied the tape, screw on the fitting and tighten it with a wrench. This will ensure a secure connection and help to prevent leaks.

Secure Areas Free of Weight

You should avoid putting any weight on or near sealed areas for at least one week while the concrete sealer cures. This will help ensure that the sealer bonding process occurs properly and that the seal is strong enough to withstand any external pressure.

During this curing period, keeping the area around the pipe clean and free of impurities is important. Any grit or particles that come into contact with the sealant can weaken the bond and cause premature failure. By following these simple guidelines, you can help ensure that your concrete sealant job lasts for years to come.

What do you use to seal a concrete septic tank pipe?

Besides the above, other sealants can also be used to seal a pipe that has been run through concrete septic tanks, so let’s discuss them in the following sections:

Hydraulic Cement

Hydraulic cement is a type that sets extremely fast and hardens after it has been mixed with water. This makes it ideal for sealing pipe running through concrete septic tanks because it can be applied quickly and easily. Hydraulic cement also resists shrinkage when it dries to prevent cracking.

Polyurethane Caulk

Polyurethane caulk is another option when sealing a septic tank pipe. Polyurethane caulk is very versatile and can be used for various applications. It also withstands extreme temperatures and is waterproof. Polyurethane caulk is also very easy to apply and won’t shrink as it dries, so it won’t crack or fall out.

Silicone Sealant

Silicone sealant is the most viable method of sealing pipes through concrete septic tanks. It is versatile and can be applied to a variety of applications. It is also waterproof and can withstand extreme temperatures. Silicone sealant is also very user-friendly and will not shrink when dried, so you won’t have a problem with cracking.

Are concrete septic tanks supposed to leak?

Concrete septic tanks are made of porous material, which is naturally permeable to water. Over time, the water pressure from the tank can cause the concrete to crack and allow water to escape. Sometimes, the problem can be fixed by simply patching the cracks with a sealant. If the leaks are severe or the tank is very old, you may need to have the entire tank replaced.

You can do a few things to prevent your concrete septic tanks from leaking in the first place. Ensure the tank is installed correctly and there is proper drainage around it. Have the tank inspected regularly and pumped out as needed. Don’t wait until there is a problem to call a professional; have someone come out and look at your tank every few years to ensure everything is in working order.

You Should Make Wise Acquisitions

Using the proper sealant when sealing pipes through a concrete tank is absolutely necessary. Hydraulic cement, polyurethane caulk, and silicone sealant are all viable options. Be sure to follow the manufacturer’s instructions carefully and allow ample time for the sealant to dry before putting weights on or near the sealed area.

Inspect the area regularly and patch any cracks or leaks as soon as they are discovered. Take these simple precautions to prolong the life of your concrete septic tank. Lastly, we hope this article has been helpful. Thank you for reading.