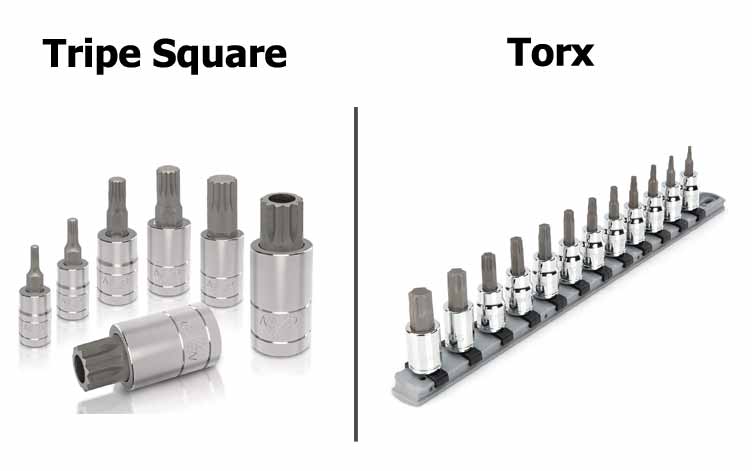

You may get confused to differentiate between Tripe Square vs Torx because while you look at them, both look pretty similar. You are right; while you see them, they seem like the same, but there are many differences between these two drill bits. Differences make them suitable for different purposes.

You Can Also Read: What Impact Bits are Suggested by an Expert?

It is very tough to differentiate between Torx and Triple Square, but experts can tell you many differences. We also make research encounter significant differences that make our job easier to distinguish between Torx vs triple square.

Torx comes in the start-like shape, while the Triple Square has three squares at all 90-degree angles. Trox use for motorcycles, vehicles, computer systems, and bicycles. At the same time, Torx only uses for vehicles. They are not the same; read the below content and found their differences. Stay tune3d to learn more.

Triple Square vs Torx: What is the Differences:

Triple Square

Triple Square comes in a trio of interlocking squares at all 90 degrees angles; you may confuse because both share the same applications. But the significant difference among their use is that Triple Square uses in autos and Torx for multiple purposes.

Highlights About Triple Square

- Triple Square is primarily used in vehicles and is found in many European vehicles. Many popular brands such as German auto manufacturers Mercedes, Audi, Volkswagen, BMW, and Porsche all prefer high-class vehicles.

- The remarkable thing about Triple Square bits is that they have some applications. You can use Triple Square with breaker bars, wrenches, and ratchets to make their performance better. But avoid using Trip Square bits with impact tools.

- Triple Square high-class material Chrome plated Vanadium makes them compatible to use for heavy-duty assignments. Chrome-plated Vanadium is the most complex material that offers excellent resistance against corrosion and other wear and tear. They can use for a longer time than other tools.

- One of the remarkable things that make Triple Square use more appealing is its high torque applications. You can use them for more significant and heavy-duty vehicles, such as driving train components and cylinder head bolts. Due to its higher torque, it is suitable to use to remove the toughest and seized components that require high force and torque.

Benefits of Using Triple Square

- Triple square is pretty easy to use in the automotive world; here are some benefits of using Triple Square that make them suitable for high-pressure auto industry jobs.

- One of Triple Square’s exceptional benefits is that the bits should stand up extra torque, Triple square product greater torque than Torx. It widely used in the job plays that are an essential part of getting the job done. It offers you greater flexibility to use to produce high torque. You can use the Triple Square with ratchets, bars, wrenches, and breakers bars to make more torque with better performance.

- Its high torque-producing feature makes it beneficial to use to remove seized bolts and nuts. It is the best tool to use where greater torque is needed. The automotive industry needs such equipment for performing their jobs, such as work with components such as train parts and cylinder head bolts. They help you to remove the seized bolts and nuts with fewer efforts.

- Durability is the central feature that people look at in anything for any tool’s better and longer performance. They manufacture with Chrome-plated Vanadium material, one of the hardest materials that offer greater resistance against wear and tear and make it suitable for a longer time.

- Triple Square widely use in popular European and German vehicle brands. If you have any of the European models with you, then you will surely need that tool to perform your tasks.

Pros:

- Durable

- Multiple uses

- Versatile

- Suitable for heavy-duty tasks

- Easy to work

Cons

- Costly

- Not better for small duty tasks

Torx

Torx are 6 point star shape; they cannot be removed with flathead screwdrivers or standard Philips. Torx is widely used in Bicycles, motorcycles, computer systems, hard disk drives, automobiles, and consumer electronics.

Highlights About Torx

- They are highly-tamper resistant because they were not developed as screwdrivers; they start using in more common and against tamper-resistant.

- They perform better than traditional flathead would and Philips, it provides better resistance came-out.

- Torx is popular to use in the construction industry due to better tamper resistance and came-out features. They perform more consistently and are better to choose in place of traditional Philips or flathead screws.

- Torx are also popular because they produce more torque than other traditional screws that also make them suitable to use for heavy-duty tasks.

Benefits of Using Torx

- Torx are best to use in place of traditional screwdrivers that experience more cam- out that make you frustrating and irritated. Torx is better because it shows reduced cam-out experience and makes your jobs smoother and quicker.

- They are just happening to look neater; with its 6-point drive, there is no need to line it up, which reduces the random look.

- Torx are manufactured with high-quality material that makes them compatible to use for multiple purposes and durable to use for a longer time than traditional Screwdrivers.

- They show great versatility, Torx widely available in the automotive world due to their improved torque. Its low cam-out makes it suitable to use for construction jobs.

Pros:

- Affordable

- Durable

- Easy to use

- Simple to restore

- Cost-effective

Cons:

- Not perform better during use with Automotive.

FAQ

1. How Many Torx Bit Sizes Are There?

The Torx bit is a star-shaped tool that is used to fasten and unfasten screws. There are five sizes available for this program: AW 10, 20, 25, 30, and 40. The Torx bit can be used with a torque wrench to tighten or loosen screws to the required specification.

2. Are Torx and Star the Same?

Torx and star are both drive types that are used to fasten screws. They are both six-pointed star-shaped, but Torx is a trademarked name for a specific type of drive, while the star is the generic descriptor for all such drives.

Torx Bits have a more pointed profile and are narrower than Star Bits, which makes them better suited for precision work.

3. Can Torx Be Used for Triple Square?

Yes, a Torx bit can be used to drive a triple square screw but it’s not recommended. Because of the shape of the Torx head, it will not provide full torque on one of the screws.

4. How Many Points Is a Triple Square?

A triple square screw driver has 12 points of contact with a driver. This means that it is the most secure type of screw fastener.

Triple Square bits have a chamfered point, which reduces material buildup on the bit and prevents it from slipping out of the head as you are driving the screws in.

Conclusion:

You have gone through our article; we have tried to provide you with suitable information to compare Triple Square vs Torx. Both of them are exceptional tools to use, but they fit differently for different purposes. For the automotive and heavy-duty tasks, Tripe square is a better choice, but for multiple purposes, such as for small duty tasks, Torx is better to use. You can choose according to your needs; both are helpful and can use as an alternative. But Triple square is suitable for heavy-duty tasks, and Torx is suitable to use in place of traditional screwdrivers.