A vacuum’s performance is highly dependent on the flow of air. In order to ensure that your vacuum is working properly, you need to be able to measure the amount of airflow.

The amount of airflow is generally indicated as CFM or cubic feet per minute. Knowing how to measure vacuum CFM will help you maintain your vacuum and ensure that it is functioning properly.

Having this information will allow you to address any issues that may arise. There are a few different ways that you can measure CFM.

Keep reading because we will go over each of these methods. This will give you the knowledge and tools necessary to measure the CFM of your vacuum cleaners.

How to Measure Vacuum CFM: Details Guide

CFM, or cubic foot per minute, is the standard unit of measurement for air flow rate. It is used to measure the amount of air that passes through an opening in a given amount of time.

This is an important measurement to know because it can help you determine how powerful your vacuum cleaners are and whether or not it is functioning properly.

There are a few different ways that you can measure CFM. An anemometer, a manometer, or a Pitot tube can be used to measure the CFM of the vacuum cleaners. Listed below are the steps necessary to use these methods.

Method 01: Using Anemometer

An anemometer is a device that is used to measure the speed of the air passing through an opening. It works by measuring the movement of air particles.

This method is well suited for measuring the air pressure of a vacuum that has a large opening. To use an anemometer, follow these steps:

Step 01: Collect a Digital Anemometer Device

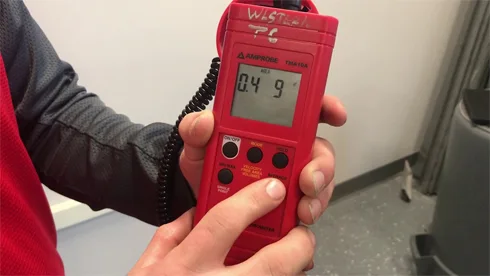

Before you can measure the CFM of your vacuum, you will need to collect a digital anemometer device. This is a hand-held device that will measure the speed of the air particles.

The anemometer device is equipped with a digital meter console where the readings will be displayed.

Additionally, an anemometer generally has a small fan to measure air flow. Furthermore, the digital anemometer device will require batteries in order to function.

Step 02: Place the Anemometer in the Vacuum Flow Path

Once you have collected the anemometer device, you will need to place it in the vacuum flow path.

The vacuum flow path is the area where the air passes through to enter and exit the vacuum. This can be either the vacuum suction or discharge hose, depending on which vacuum you are using.

Step 03: Turn on the Vacuum

Once you have placed the anemometer in the flow path, you will need to turn on the vacuum. The vacuum should be running at full power when taking the air flow measurement.

Step 04: Take Measurements

Now it is time to take some measurements. With the vacuum running at full power, hold the anemometer and take readings of the air-speed. The digital anemometer device should give you readings in CFM. You can take multiple readings to get an accurate average.

Step 05: Record the Data

Be sure to record all of the data that you have collected. This will include the CFM readings as well as the vacuum’s power setting. You will need this information when troubleshooting any issues with your vacuum pump.

Method 02: Using Digital Manometer

Another device that can be used to measure air flow is a digital manometer. This device measures the pressure differential between two points.

It is commonly used to measure the air watt in the duct. However, it can also be used to measure the CFM of the central vacuum system. To use a digital manometer, follow these steps:

Step 01: Collect a Digital Manometer Device

Just like with the anemometer, you will need to collect a digital manometer device before you can take any measurements.

A digital meter console is included with this hand-held device. The digital manometer also has a pressure sensor. This device will require batteries in order to function.

Step 02: Place the Manometer in the Vacuum Flow Path

With the digital manometer device in hand, you will need to place it in the vacuum flow path. The placement of this device is important because it needs to be able to sense the pressure differential.

Step 03: Turn on the Vacuum

Now that the digital manometer is in place, you will need to turn on the vacuum. The vacuum should be running at full power when taking the measurements.

Step 04: Take Measurements

Take the manometer and place it in your hand. Hold it in such a way that you are able to read the pressure differential.

Now, take readings of the pressure differential. You can see the pressure differential readings on the digital meter console. Be sure to take multiple readings to get an accurate average.

Step 05: Record the Data

Once you have collected all of the data, be sure to record it. This will include the pressure differential readings as well as the vacuum’s power setting.

Method 03: Using a Pitot Tube

The final method for measuring the CFM of a vacuum is by using a Pitot tube. This is a device that measures the total pressure. It can also be used to measure water lift.

It can be used to measure the airflow in ducts or in a vacuum. This device has total pressure and static pressure sensors that are measured the air velocity pressure. To use a Pitot tube to measure the CFM of a vacuum, follow these steps:

Step 01: Collect a Pitot Tube

Just like with the anemometer and digital manometer, you will need to collect a Pitot tube before taking any measurements. Doing so will facilitate the measurement process.

Step 02: Place the Pitot Tube in the Vacuum Flow Path

The next step is to place the Pitot tube in the vacuum flow path. The placement of this device is important because it needs to be able to sense the total pressure. The best place to put the Pitot tube is at the end of the suction hose.

Step 03: Turn on the Vacuum

Now that the Pitot tube is in place, you will need to turn on the vacuum cleaner. The vacuum should be running at full power when taking the measurements.

Step 04: Take Measurements

With the vacuum running at full power, take readings of the total pressure. The total pressure readings will be displayed on the digital meter console. Be sure to take multiple readings to get an accurate average.

Why is CFM Important in a Vacuum?

CFM is important because it is a measure of the vacuum’s performance. Generally, the higher the CFM means that your vacuum is doing a better job at suctioning.

A vacuum with a low CFM may not be able to pick up all of the dust and debris that you are trying to vacuum. So, if you want to get the most out of your vacuum cleaner, make sure that you check the CFM before making a purchase.

What are Some Factors that Can Affect the CFM of a Vacuum?

There are several factors that can affect the CFM of a vacuum. One factor is the type of filter that you are using. A clogged filter will cause the CFM to decrease because it restricts atmospheric pressure.

Another factor is the power setting of the vacuum cleaner. A higher power setting will result in a higher CFM. Finally, the size of the vacuum opening can also affect the CFM. A smaller opening will result in lower vacuum pressure.

Frequently Asked Questions:

There are some questions that are commonly asked about vacuum CFM. Here are some of the most common questions and their answers.

1. What Is the Typical CFM Rating Of a Vacuum?

The CFM of a vacuum can vary depending on the model. A typical CFM rating for a vacuum is around 50 to 100 CFM.

2. How Do I Know If My Vacuum Has a Good CFM Rating?

A good way to determine the CFM rating of your vacuum is to check the manufacturer’s specifications. You can also determine your vacuum’s CFM rating by measuring it. Generally, a higher CFM rating can pick up more debris. If your vacuum’s CFM rating is 125 or higher, then it is considered a strong vacuum.

3. How Can I Improve the CFM Rating of My Vacuum?

There are a few ways that you can improve the CFM rating of your vacuum. One way is to replace the filter with a more efficient one. You can also try to increase the power setting of the vacuum. Finally, you can try to clean or replace the vacuum opening.

4. What Happens If CFM Is Too Low?

If the CFM of your vacuum is too low, it can lead to reduced suction power. This can make it difficult to pick up debris. Additionally, a low CFM can cause the vacuum motor to overheat and eventually fail.

Conclusion

We hope that you now have a better understanding of what vacuum CFM is and how to measure vacuum CFM. You can also realize the importance of having a high CFM rating as well as some of the factors that can affect it.

CFM can be measured using any method that is most comfortable to you, but an anemometer and manometer will yield the most accurate results over the Pitot tube method. Whichever method you choose, make sure to use it consistently to get the most accurate results.