Like a missing puzzle piece can ruin the whole picture, hairline cracks can ruin concrete and cause bigger problems. Those hairline cracks may seem small, but they can weaken the structure and lead to water damage and mold growth. But don’t stress, sealing those cracks is easier than you think.

To seal hairline Concrete cracks, first, you must clean the surface thoroughly and remove any debris. Then moisten the concrete and apply a sealant. You can use epoxy, latex, or mortar mixed sealer for a seal. After that, smooth it out and let the sealant dry.

Today we’ll guide you through the steps to seal hairline cracks in concrete. We’ll explain what causes those pesky cracks and why it’s crucial to fill them. So keep reading.

How to Seal Hairline Cracks in Concrete: Steps to Follow

STEP 1. Clean the Surface and Remove Loose Debris

STEP 2. Moisten the Crack to Prepare it for Sealing

STEP 3. Mix a Suitable Concrete sealant

STEP 4. Apply the Sealant to the Crack

STEP 5. Smooth the Sealant Over the Crack

STEP 6. Allow the sealant to cure

If you’re encountering hairline cracks in your concrete, remember that they can lead to bigger issues if not taken care of immediately. There’s no need to worry; sealing them is a simple process that can be done quickly and affordably. Here’s all you need to know to get the job done right:

STEP 1. Clean the Surface and Remove Loose Debris

Before fixing the tiny crevices on your cement surface, grab a trowel or putty knife to scrape away any dirt or debris. Ensure the crack is completely free of loose material, as any remaining debris could prevent the filler from adhering properly.

You can also use a wire brush or compressed air to remove dust or debris. Once the surface is clean, the vacuum removes any remaining particles.

STEP 2. Moisten the Crack to Prepare it for Sealing

The next step in sealing hairline cracks in concrete is to ensure that the surface is damp enough to allow the sealant to bond properly. To do this, take a spray bottle filled with water and mist the crack, thoroughly moistening it without becoming overly saturated.

This’ll help the sealant adhere to the concrete and prevent it from cracking or flaking off over time. Once the crack is moistened, you can mix a suitable concrete sealant that’ll fill the crack and create a durable, long-lasting seal.

STEP 3. Mix a Suitable Concrete Sealant

The two sealants you should consider to seal hairline cracks in concrete are:

#1 Epoxy or Latex Concrete Sealant:

It’s best to apply an epoxy or latex patching product mixed for a smooth and sturdy finish. But if the cracks are wider than ⅛-inch, this method may not be suitable. In that case, you may consider using a mortar mix concrete sealant.

#2 Mortar Mix Concrete Sealant

Mixing up your mortar is a simple and effective solution for larger imperfections in your concrete surfaces. To create your mix, combine one part Portland cement with three parts masonry sand and add just enough water to form a thick paste.

This mix is easy to apply with a trowel or a putty knife and will fill in the cracks and gaps in your concrete.

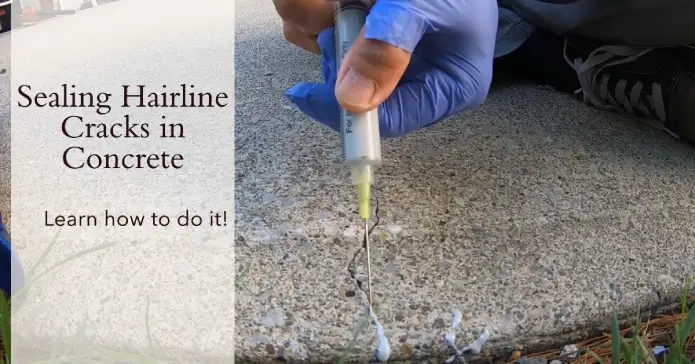

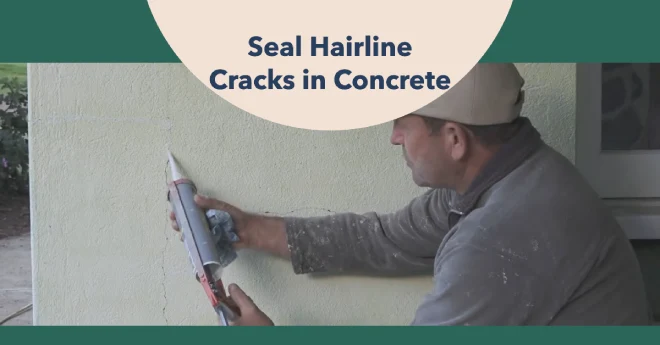

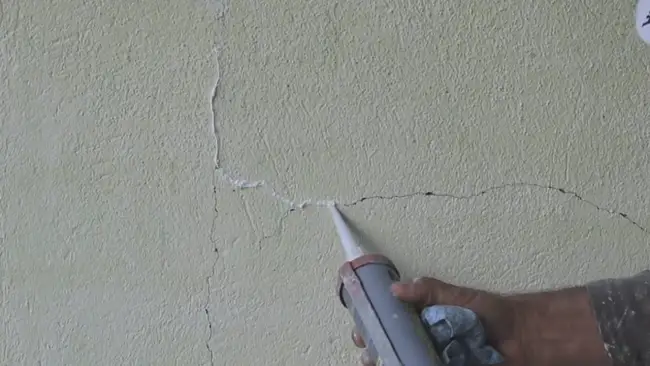

STEP 4. Apply the Sealant to the Crack

Smoothly spread the sealant over the tiny fractures with a squeegee or roller. This is a crucial step in preventing further damage to your solid surfaces. Make sure to distribute the sealant and fill the crack evenly.

Apply multiple layers of sealant, waiting for each layer to dry before applying the next. The sealant should be applied slightly above the surface of the crack to ensure it fills the crevice.

STEP 5. Smooth the Sealant Over the Crack

Then you must ensure the sealant blends seamlessly with the surrounding surface, giving your solid surfaces a polished look. After applying the sealant to the crack, take a putty knife or trowel and smooth the adhesive over the gap.

Make sure to spread the sealant evenly and remove any excess material. The sealant should be level with the concrete surface, so use the putty knife or trowel to scrape away any excess.

Work slowly and carefully, ensuring not to disturb the sealant already applied. Once you’ve achieved a smooth finish, allow the sealant to cure for the recommended time before using the surface.

STEP 6. Allow the Sealant to Cure

After smoothing the sealer, let the sealant cure properly before using the surface, so give it the recommended amount of time to fully set. This can vary depending on the type of sealant used, so be sure to read the instructions carefully.

Generally, it takes a few hours to a few days for the sealant to fully cure. During this time, keeping the area dry and free from traffic or heavy objects is essential. This will ensure the sealant is given the best chance to bond properly and provide a long-lasting fix for your hairline cracks.

What Causes Hairline Cracks on Concrete?

Hairline cracks on concrete can be unsightly and concerning, but they are common. These cracks typically appear in concrete surfaces due to various factors, such as:

A. Stress Relief:

If you’ve noticed any tiny fractures in your concrete, it could be due to stress relief caused by excess tensile stress. This occurs when the stress created is more than the capacity to resist, forming a crack.

Identify and address the underlying cause of the stress, whether due to a lack of reinforcement or excessive weight placed on the concrete. Once the root cause is fixed, you can seal the hairline cracks using a suitable sealant.

B. Thermal Contraction:

Concrete can become brittle when exposed to extreme temperatures, such as seasonal changes, and develop tiny fractures. Leaving these hairline cracks untreated can cause larger problems because moisture can seep into the concrete and cause further damage.

C. Moisture Exposure

In the same way, a leaky roof can damage a home’s foundation, and exposure to moisture can weaken and erode your concrete’s structure. When exposed to moisture, concrete absorbs the water and dries repeatedly in the sun, leading to hairline cracks.

These cracks, although small, can allow more moisture to penetrate the structure and cause further damage. Fill these cracks in concrete to prevent water from seeping in and causing more significant issues in the future.

D. Chemical Damage

To prevent chemical damage to your concrete, you must be aware of the three key factors that can cause it.

#1 Carbonation

Carbon dioxide invited itself to the party and caused a chemical reaction that weakens and rusts your beloved concrete. However, there are ways to prevent and even repair the damage caused by carbonation.

One solution is to seal the hairline cracks in your concrete to prevent carbon dioxide from entering and reacting with the calcium hydroxide. You can also use coatings and sealers specifically designed to resist carbonation.

#2 Sulfate Attack

Your building may be harmed by sulfate attacks depending on the soil your building is built on. This occurs when sulfates from the soil or groundwater react with the cement in the concrete, causing it to expand and crack.

This can be a serious problem as it weakens the concrete structure and compromises its durability. To prevent sulfate attack, use a concrete mix with low permeability and properly seal any cracks or joints in the concrete.

#3 Alkali-Silica Reaction

You may not realize it, but the type of aggregate used in your concrete can cause a chemical reaction that weakens the structure over time. This is known as the alkali-silica reaction.

This reaction occurs when alkalis in the cement mix with the silica content of the aggregates. The result is a gel-like substance that absorbs water and increases the volume of the concrete.

As a result, the concrete can crack and decay, leading to structural damage. To minimize the corroding of metal reinforcement, take proactive measures to address this issue.

Why Is It Critical to Fill Cracks in Concrete?

Whenever cracks appear in concrete, you must fill them as soon as possible to avoid structural damage. Here are some reasons:

To Prevent Structural Damage

Preventing structural damage is crucial for your home’s long-term stability and safety. Cracks in slabs or walls can result from settling. Still, a more serious problem might be a faulty foundation or improperly mixed concrete.

If left untreated, these structural problems could collapse and endanger the lives of those living in the home.

To Prevent Corrosion of Metal Reinforcement

Protect the metal reinforcement from corrosion by applying a rust inhibitor or coating. Corrosion occurs when chloride ions come into contact with the steel reinforcement, forming hydrochloric acid. This eats away at the steel and causes concrete cracks.

How to prevent future hairline cracks in concrete?

To ensure a strong and durable concrete surface, take preventative measures. Techniques like fog nozzles, plastic sheeting, and microfibers in the mixture can increase the tensile capacity of the material by up to 30%.

Dampen the subgrade and formwork before starting the concrete process to prevent future problems. And applying an evaporation retardant will also help avoid future problems.

It’s crucial to remove any excess water from the subgrade and formwork before placing concrete to prevent cracking due to shrinkage. Windbreakers and sunshades can also reduce wind velocity and surface temperature, respectively.

Which concrete repair products are suitable for hairline cracks?

One effective product to consider is a micron-sized sealant that can penetrate and fill those hairline cracks. This type of sealant is designed to remain flexible, durable, and waterproof in hot and freezing temperatures, ensuring a long-lasting repair.

Choosing the right product can effectively seal those cracks and prevent further damage to your concrete surfaces.

Can I just paint over concrete hairline cracks?

You might be tempted to slap on a fresh coat of paint, but beware, ignoring those tiny fractures in your concrete can lead to more significant issues. At the same time, covering them up with a fresh coat of paint may be tempting. Cracks may become more noticeable because this won’t fix the underlying problem.

Instead, properly address the cracks by filling them with a suitable filler and then sanding the area to ensure a smooth surface before applying a new coat of paint. Addressing these hairline cracks properly ensures that your concrete surface remains strong and durable for years.

Maintain Concrete Surfaces to Avoid Cracks: Use Quality Sealant

To prevent future hairline cracks, you must properly maintain your concrete surfaces. This includes regular cleaning, avoiding heavy loads or impacts, and using a quality sealant.

Taking the steps above not only improves the appearance of your concrete but also protects it from major structural damage. Think of it as putting a band-aid on a cut. It may be small, but if left untreated, it can lead to bigger problems.

By taking these preventative measures, you can avoid the headache and expense of repairing larger cracks in the future. Remember, a little effort now can save you a lot of trouble later on.