As part of plumbing work, it is necessary to join plastic pipes together. This is where PVC glue comes in. It is a type of adhesive that helps to bond the plastic pipes together.

The good thing about this glue is that it is solid and durable. You may also use PVC glue to repair leaks. When using PVC glue, it is recommended that you must know how much pressure can PVC glue hold.

Knowing this will enable you to determine whether the glue will hold under a given pressure. We will discuss this in more detail below, so keep reading on.

How Much Pressure Can PVC Glue Hold? Find out the Answer

PVC glue, also known as PVC solvent cement, is known to be an effective adhesive to use in the plumbing industry. This is because it can withstand high pressure. However, how much pressure can PVC glue withstand?

Some PVC glues can withstand pressures of up to 160 pounds per square inch. Therefore, they are capable of holding up to great pressure without breaking. However, not all PVC glues are the same. Some are only capable of withstanding a low amount of pressure.

On the other hand, there are also heavy-duty PVC glues that can hold under even pressure applications. With regard to all types of PVC glue, the average pressure that it can hold is approximately 100 to 170 PSI.

Consequently, it is a strong and durable adhesive that can be used for PVC coupling, PVC pipe fittings, and other plumbing purposes. Now that you know how much pressure PVC glue can hold, you can confidently use it, knowing that it will not break under pressure.

What Components are Used in Making PVC Glue?

After learning how much pressure PVC cement can hold, you may now be curious about the ingredients used in making this product. PVC cement or glue is made from many ingredients. Below are some of the most common ingredients used:

1. Ethyl Ketone

Ethyl ketone, also known as butanone, is a colorless, flammable liquid that is used as a solvent. This ingredient is used to make PVC cement because it helps produce a strong and durable adhesive.

2. Cyclohexanone

Cyclohexanone is another common ingredient used in making gorilla PVC glue. This organic compound has the formula (CH2)5CO. The six-carbon cyclic molecule containing a ketone functional group composes the molecule.

There is a slight acetone-like odor to this colorless oil. There is miscibility between the oil and organic solvents. In general, it is used as a precursor to nylon.

3. Tetrahydrofuran

Tetrahydrofuran is an organic compound with the formula (CH₂)₄O that is used as a solvent in making PVC cement. The organic liquid is water-miscible and has a low viscosity. Oxolane is another name for this liquid. Polymers are usually synthesized from this liquid.

4. Acetone

Acetone is a colorless, flammable organic compound with the formula (CH₃)₂CO. It is also known as dimethyl ketone or propanone. Acetone is miscible with water. This substance is used as a solvent in the production of PVC cement because it fosters a strong adhesive bond.

Why Should You Use PVC Glue?

PVC glue is well known for many reasons. Plumbers prefer to use PVC glue for every plumbing application. Below are some of the reasons why you should use PVC cement:

1. Fast Drying Time

PVC glue has a very fast drying time. This is one of the reasons why many plumbers prefer it. This is very convenient because you do not have to wait for a long time before moving on to the next step.

2. Strong Adhesive Bond

Plumbing jobs require a strong adhesive bond. This is because the PVC pipe is constantly subjected to water pressure. PVC cement can provide a strong adhesive bond so that you can be confident that your CPVC pipe will not leak.

3. Easy to Use

PVC cement is very easy to use. You simply have to apply the glue to the surface of the PVC material and then join the two pieces together. The whole process is very simple and straightforward.

4. Waterproof

Another great advantage of PVC primer is that it is waterproof. This means that you do not have to worry about your PVC fitting leaking, even if they are constantly exposed to water.

5. Withstands High Pressure

PVC piping is subjected to high pressure whenever water flows through them. PVC cement is designed to withstand high pressure. You can ensure that your PVC pipe will not leak or break.

6. Durable

It is important to select an adhesive that will last for a long time. You do not want to have to keep replacing your adhesive every few months. PVC cement is a very durable adhesive. This means that it can last for a long time. There is no need to worry about the glue breaking down with time.

7. Flexible

PVC glue is also very flexible. This means that it can accommodate slight movements without breaking down. This is important because PVC pipe is constantly expanding and contracting due to changes in water pressure.

8. Resistant to Chemicals

The PVC pipe is often exposed to harsh chemicals. PVC glue is resistant to many of these chemicals. Thus, even if it is in contact with these substances, it will not decompose.

9. Save Time and Money

If you use PVC cement, you can save time and money. This is because it dries quickly and forms a strong bond. This means that you do not have to waste time and money on repairs.

10. Can be Used on Many Materials

PVC glue can be used on many different materials. This includes plastic, leather, and even glass. This means that you can use it for a variety of purposes.

What to Consider When Buying PVC Glue?

To obtain the desired result, it is essential to choose PVC glue that is of high quality. A number of factors should be considered in this regard. Below are some of the factors that you need to consider:

1. Strength

One of the most important factors to consider is the strength of the adhesive. The glue should be strong enough to hold the pipes together under high pressure. Choose one that has high tensile strength.

2. Viscosity

Another factor to consider is the viscosity of the glue. This refers to the thickness of the adhesive. A high-quality PVC glue should have the right viscosity so that it can be easily applied to the surface of the PVC pipe.

3. Drying Time

The drying time of the adhesive is another important factor to consider. A high-quality PVC glue should have a fast drying time. This is because you do not want to wait for a long time before moving on to the next step.

4. Temperature Resistance

It is also important to choose an adhesive that can resist high temperatures. This will ensure that the glue will not break down under extreme conditions.

5. Odor

The adhesive should also have a low odor. This is because you do not want the glue to produce a strong smell that can be unpleasant.

6. Shelf Life

The shelf life of the adhesive is another factor to consider. You should choose one that has a long shelf life so that you can use it for a long time.

How to Join Plumbing Pipe Using PVC Glue?

Knowing how to join plumbing pipes using PVC glue properly is a very important skill. This is because it can save you a lot of time and money. Below are the steps that you need to follow for gluing PVC pipe:

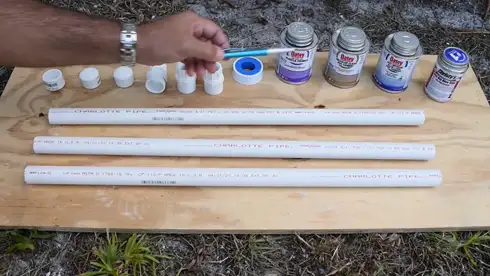

Step 01: Prepare the Pipe

The first step is to prepare the PVC pipe. This involves cutting the PVC pipe to the correct length and then cleaning the surface. It is very important to make sure that the surface is clean because this will ensure that the glue adheres properly.

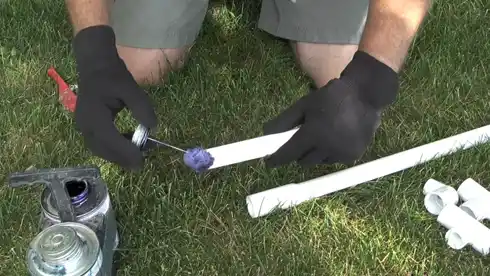

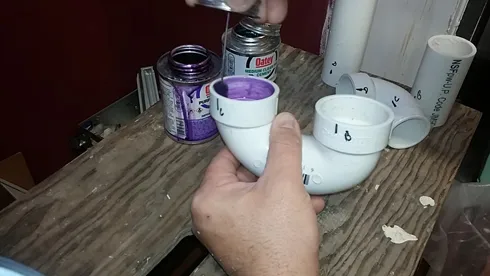

Step 02: Apply PVC Glue

The next step is to apply the PVC glue. You should apply a generous amount of glue to both surfaces. Make sure that you spread the glue evenly.

Step 03: Join the Pipes

Once you have applied the glue, you can then join the two pipes together. You should align the pipes so that they fit snugly together.

Step 04: Apply Pressure

After joining the pipes, you should apply pressure. This will help to ensure that the bond is strong.

Step 05: Allow the Glue to Dry

Once you have applied pressure, you should allow the glue to dry. You should not subject the PVC pipe to any type of stress during this time.

By following these steps, you can join plumbing pipes using PVC glue. This is a very strong adhesive that can save you a lot of time and money.

Frequently Asked Questions:

Several questions are frequently asked regarding PVC glue. Below are some of the most frequently asked questions:

1. How Long Does PVC Glue Take to Dry?

The drying time of PVC glue varies depending on the quality of the adhesive. In 30 seconds, a high-quality PVC glue can hold the pipes together. The glue will take about 15 minutes to dry for a hard joint. It will completely cure in about 2 hours.

2. Is PVC Glue Permanent?

PVC glue is a powerful adhesive. Once it dries, it forms a permanent bond. This means that you will not be able to remove the PVC pipe without causing damage.

3. What Is the Shelf Life of PVC Glue?

The shelf life of PVC glue varies depending on the quality of the adhesive. Generally, high-quality PVC glue has a shelf life of about three years.

4. Can You Use PVC Glue on Metal Pipes?

No, you should not use PVC glue on metal pipes. This is because the glue will not adhere properly to the surface of the metal. The adhesive will adhere well to plastic pipes.

Conclusion

Now that you have an idea of how much pressure can PVC glue hold, you can ensure a secure connection to your pipes. Be sure to choose high-quality PVC glue so that the bond is strong and long-lasting.

Just follow the factors that we have listed above to choose the optimal PVC glue. You can also join plumbing pipes using PVC glue like a pro by following the steps we have provided.