Pulley is installed in the motor shaft to increase the power, speed and to make changes in the direction of motion. It is a necessary item to use in the motors to make motors more beneficial and ease their work.

You may need maintenance of your motor and pulley, or if there is any fault with the pulley, you may need to remove its pulley. If you are a technician, it may be easier for you, but it is a complex task for the beginner.

You can make it easier by reading the below instructions in our content about removing the pulley from the motor shaft.

What do you need to do?

Before setting on your work, you need to make some arrangements to make your task easier, safe, and perfect when complete.

Electric motors are hazardous, so when you remove the pulley from the motor shaft, make sure you have worn all the safety gadgets.

You also need to do care while removing the pulley; if you do not have enough safety knowledge, then do not try this because nothing is important than your safety.

Arrange the Required Materials and tools

You are nothing if you do not have the proper tools and required material with you. So before setting on the work, arrange the necessary tools and materials first.

What tools do you need?

You should have the following tools for your safety and to perform your pulley removing task.

- Safety Glasses will protect your eyes.

- Pulley puller to pull the pulley

- ¼ inch quick connect to the half-inch socket conversion bit

- ¼ inch quick connect impact driver

- 5/32 inches Allen key

- 5/8 inches socket

- Non-contact voltage stick for safety purpose while pulling items

- Digital Multimeter

- Penetrating oil or Rust Buster

- You may also need some handy tools.

Steps to remove pulley from the motor shaft

Once you have arranged all the above handy tools and materials, follow these simple steps to remove the pulley from the motor shaft.

Step one

Your safety is our priority, so always lock out the machine on that you are working before doing the work. It may take a minimum of thirty seconds. It is better to leave it for a minute to properly lockout.

If you go in a hurry, you may hurt your fingers, and sometimes your fingers cut very seriously. Do that only for your safety.

Step two

The second step is to remove the access panels; you will need to unscrew the screws with the Allen key for removing the access panels.

Step Three

In that step, you will need to check that the motor is adequately disconnected from the power. When you switch off the engine, it is not enough. You need more assurance to check the motor. For that purpose, we will recommend you to use the sensitive digital multimeter.

Always double-check the machine before working, take the digital multimeter, check the L1-L2, then L1-L3, and then L2-L3, and also do not forget to check the phases to the ground.

If your motor is working on the single phases, then watch out for the capacitors that may hold the charge even the motor is switched off.

Step Four

Now take your non-contact stick to depress your motor contactor. This one is a triple check; if your digital multimeter fails, it will detect the current. If there is no detection, then it is safe to work.

You may wonder to see why I am asking you to check the motor again and again. We have seen many instances even the motor was switched off. So we are asking for your safety.

Step Five

You will need to remove the belt; you will remove the belt with your hands. But make sure you have worn the plastic gloves for safety. Belt sometimes stuck and hurt your hands. After that, you will need to remove all screws, unscrew the screws gently.

Step Six

Now apply the penetrating oil or rust buster on all areas of the pulley shaft as much as possible and leave it for a few minutes. You can repeat the oiling two or three times if you see the pulley poorly covered with rust or dust.

Step Seven

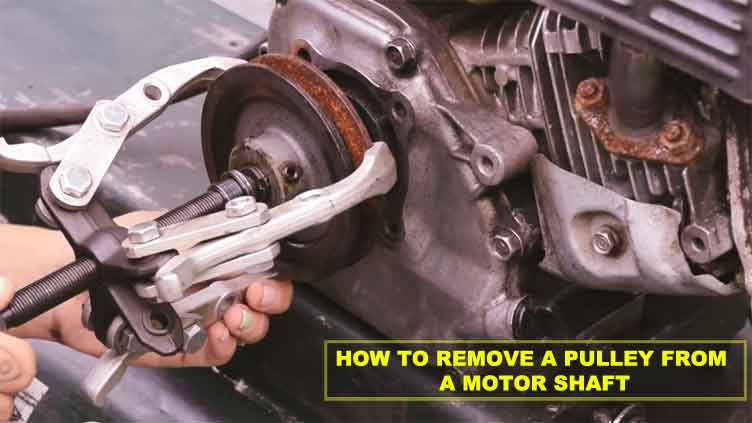

Finally, you need to remove the pulley; after applying the penetrating oil, when you ensure oil properly penetrates inside the pulley shaft, take the pulley puller.

Set up the pulley puller and then connect it with the impact driver and pulse the trigger. Now gently pull the pulley outside, do not apply force too quickly; it may damage your pulley.

Another Mechanic tool Article: Expert Recommendation for Seal Puller

Helpful tips

If your pulley is stuck and you face the problem of removing the pulley from the motor shaft, then the following tips will help you remove the pulley.

If you face the problem of removing the pulley, you can pull it out, and sometimes you may need to knock it out with a drift.

If you need some clearance behind the sheave, you should use the brass rod and a hammer to smash the sheave. Remove the pulley, clean it and polish the exposed parts of the shaft.

If you face too many problems, it is better to remove the motor from the frame and place it on the bench and work on it.

Final Thoughts

We often need the removal of the pulley from the motor shaft. It is a tough job, but with proper guidelines, you can do it efficiently. Removal of a pulley from the motor shaft is not rigid but needs too much care. So never forget to follow the safety instruction as we have recommended.