The word “pex” stands for “cross-linked polyethene.” It is such a form of tubing that prepares from polyethene of high density. We use it for floor tubing and water supply.

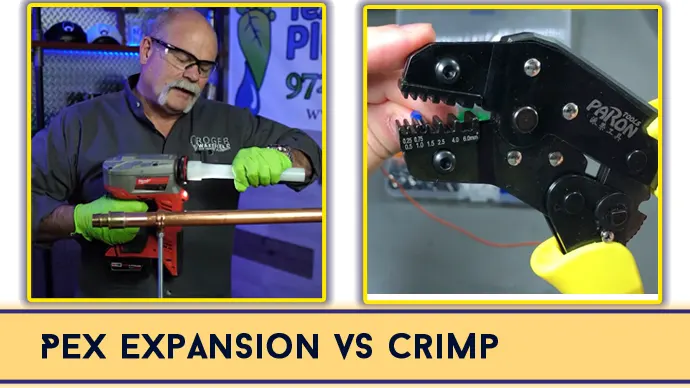

PEX expansion is a special type of tool that expands and fit the pipes together. It creates one/eight turns between expansions. It broadens one end of PEX tubing. We can fit this broad and wide end on the brass fitting easily.

A crimp is the end product of a crimping tool. The crimping tool is a hand device that joins two metal pieces or ductile material together. Ductile materials include wires and metal plates.

During conjoining two pieces of metal, one or both pieces get deformed. This deformation holds the pieces together. We can join a connector to the cable by this process.

After an introduction, we will now discuss the difference between both PEX expansion and crimp.

The Difference in Preparation:

Preparation of PEX Expansion:

PEX expansion needs pipes just like polyvinyl chloride pipe. The shape of the PEX should be square. It should be neat and clean. The expander tool expands the expander rings according to the instructions and specifications of the manufacturer.

If we have the improper expansion, it leads to the leakage and inefficiency of the pipe. It shortens the life span of the pips and tubes and causes wastage of money.

You can attain your target of high-quality connections by the maintenance of PEX expansion. Lubrication is essential for its proper use.

Preparation of The Crimp:

The preparation of the right crimping tool is a considerable part when you are performing the crimping process. Choose the process that meets your requirements and prevent loss of time during the process.

In the preparation of the crimp, the crimp connectors are joined. It involves the inserting of the stripped end of the wire into only a small portion of the connector. Then it gets deformation by crimping it around the wire tightly.

The crimping process includes a specialized crimping tool that is crimping pliers.

The Difference in Working:

Working of PEX Expansion:

PEX expansion widens the pipes and tubes. It also enlarges the sleeve. It makes both pipes and sleeves enlarged to slide in the fitting easily.

The plastic sleeve slides and joins on the connection point. As we know, PEX has a capacity of expanding and contracting; it can shrink back to its own original size and shape around the fitting. It makes the fitting tight.

Working of The Crimp:

The three main elements in the crimp include

- A terminal

- A wire

- A crimping tool

Crimps are designed in such a way that they connect the wire strands strongly together. This connection has no gaps between the strands. It avoids the entry of both oxygen and moisture, thus prevent corrosion (rusting). In short, it reduces the space and also works to reach the wire to the pre-set level.

The Difference in the Fitting Process:

Fitting of The PEX Expansion:

PEX expansion is the modern and advanced process of piping supply. The fitting of pex expansion involves the slid of the pex ring on the end of the pipe. Mostly, rings stop at the end, but a little gap should be created at the end before making a connection if they do not stop.

Now, the pipe is stretched to a suitable width. If we have an expansion device, the pipe expands according to the advice of the supplier.

We should insert the tube into the fitting until there is no space between the ring shoulder and the fitting shoulder. Different tubing requires fitting differently.

- The fitting should be standard.

- The fitting involves the application of the sleeve.

- The fitting should be tested after twenty-four hours

The temperature has an effect on the expansion, so it can indirectly affect the fitting process. At high temperatures, more expansion takes place. At low temperatures, there is less expansion but more shrinking of the pipe and sleeve.

Fitting of The Crimp:

The two most important parts of the crimping process are

. A crimping ring

. A crimping tool

The process involves the attachment of the pipe to the crimp fittings. Firstly, the crimp ring is put on the tube then the loop inserts in the tube. This crimp ring is joined to the tube via the crimping tool.

- The fitting should be standard.

- The fitting involves the application of tools that require calibration.

- The fitting should be tested instantly.

After discussing the difference between pex expansion and crimp, we will talk about their advantages and disadvantages.

Advantages and Disadvantages of PEX Expansion:

We know that this expansion causes flexibility. It can cause a change in direction and lessens the links ad connection number. This flexibility expands and shrinks the tubes to their original shape. In this way, it resists the damage of frozen water in the tubes and pipes.

The fitting process is easy and fast. It also reduces the leakage points and also avoids corrosion. It is more durable than copper or brass.

But it also has some disadvantages. Pests and chemicals can damage pex expansion. It does not occur in areas where the temperature is high. It is sensitive to the radiations coming from the sun to the Earth. As pex is partially permeable, water can easily enter the pipe.

Advantages and Disadvantages of The Crimp:

Crimp fittings are relatively less expensive. If you perform this fitting correctly, the crimping provides good linkage. Suppliers of the fitting equipment and rings are easily available. So it is easy to purchase them from the market.

The crimp has less and negligible advantages. So most professional plumbers prefer the crimp over the pex expansion.

We provided you with a complete way to distinguish between both types of linking tools.

Final Thoughts:

There is a difference in the preparation, working and fitting of pex expansion and crimp. You can use both processes to make connections. Both have their own cons and pros. But most plumbers give priority to the crimp as it is more reliable than pex expansion.