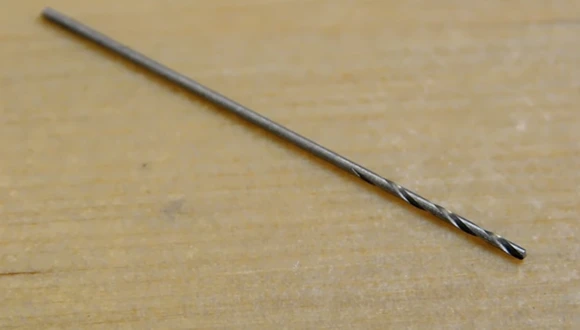

It is no secret that drilling through tough materials can be challenging for anyone who has ever used a drill. Even with the best drill bits, it’s not uncommon for them to break from the sheer amount of force required.

But why do my drill bits keep breaking, and is there anything that can be done to prevent it? Believe it or not, there are some obvious reasons that drill bits might be breaking more often than you’d like.

As we go along in this post, we’ll explore some of the most common reasons for drill bits breaking. The article will also offer some tips on how to prevent it from happening.

Why Do My Drill Bits Keep Breaking : 16 Reasons

There are many reasons that could be causing drill bits to keep breaking. In this article, we will explore 16 of the most prevalent ones.

1. Flexing the Bit

When drilling, it’s important to keep the bit from flexing too much, as this can break the bit. The best way to avoid this is to use a drill guide. A drill guide is a metal sleeve that goes around the bit and helps to keep it straight.

It’s important to select a drill guide that’s the same size as the bit, so that the bit can move freely inside the guide. If the guide is too small, it will constrict the movement of the bit and cause it to bind.

In the case of a guide that is too large, it will allow the bit to flex too much and break. By using a drill guide, you can help prevent breaking your drill bits.

2. Too Much Side Loading on the Bit

One of the most common mistakes made when drilling is known as side loading, which occurs when the bit is not perpendicular to the workpiece. When this happens, the bit can become stuck or break, causing costly delays and damage.

Side loading can also cause the hole to be larger than intended or to be drilled at an incorrect angle. To avoid these problems, it is important to ensure that the bit is always perfectly aligned with the workpiece before beginning to drill. By following this simple rule, you can help prolong the life of your drill bits and avoid costly mistakes.

3. Drilling pressure

The high drilling pressure can break the drill bits. When the drill bits are under high pressure, they are forced to rotate at high speed. This causes the drill bits to heat up and eventually break. The weakened drill bits can then fall into the well and cause harm to the equipment and surrounding area.

In some cases, the broken drill bit can also cause an explosion. To prevent these accidents from happening, it is important to follow the safety guidelines and use the proper equipment when drilling.

4. Cheap or Crappy Bits

Crappy or cheap bits are known to cause serious damage to drills, as well as render the bits themselves useless. The main problem with these types of bits is that they’re made from softer metals, which means they wear down much more quickly.

The tips of these bits are often not properly hardened, making them more susceptible to breaking. As a result, it’s best to avoid cheap or crappy Bits altogether and stick with higher quality bits that will last longer and provide a better overall grilling experience.

5. Bending Stress

When a drill bit is used, the metal is subject to bending stress. This structural force can cause the metal to break and fail. The breaking point is typically at the weakest point in the metal, which is usually where the bit meets the shaft. When the metal breaks, it can cause the drill bit to shatter, break off from the shaft, or become bent.

The drill bit may even snap in half. Depending on the severity of the break, this can result in serious injury to the operator or physical harm to the equipment.

As a result, it is important to be aware of how much stress a drill bit can take before it breaks. When in doubt, it is always best to err on the side of caution and use a higher-quality bit that can withstand more force.

6. Rough Use

When it comes to drilling, it is important to realize that there is a big difference between light use and heavy, or what is known as “rough,” use. While both will eventually break the drill bit, rough use will do so much more quickly. The main reason for this is that rough use creates more friction, which in turn creates more heat.

This heat can make the metal weaken and break. Rough use can also cause the drill bit to become misaligned, making it more likely to break when it hits an obstacle. For these reasons, it is important to take care not to overdo it when drilling, in order to extend the longevity of your drill bits.

7. Fetching up in the Hole

If the drill bit becomes stuck, or “fetch up,” in the hole, it can break, leaving the drill bit unusable. Most fetching up is caused by drilling into knots in the wood.

The hard surface of the knot causes the drill bit to grab, making it difficult to remove. The entire drill bit may break while trying to remove it from the hole. If this happens, the best course of action is to start over with a new drill bit.

When drilling through a hard material, such as concrete, the risk of fetching up and breaking your drill bit is increased. To avoid this problem, it’s important to drill slowly and use a slower speed setting on your drill.

You should also keep the drill bit away from the edge of the hole to help prevent it from hitting the wall. With a little care and attention, you can avoid fetching up your drill bit, which can lead to a break.

8. Insufficient Quality

One of the most important aspects of any drilling project is the quality of the drill bits being used. Drill bits are available in many different types and sizes, but one thing they all have in common is that they need to be able to withstand many types of wear and tear over the course of their usefulness.

Drills of insufficient quality can break the drill bits. The chuck, which is the part of the drill that holds the drill bit in place, can loosen over time with use. If the chuck is not properly tightened, the drill bit can slip and become damaged.

The gears inside the drill can strip, causing the drill to stop working properly. If you are using a drill with faulty parts, it is more likely that the drill bit will break.

Unfortunately, poor-quality materials can quickly break down, causing the drill bit to fail. This can even cause the entire drill to fail, which can be extremely dangerous.

To avoid this type of disaster, it is essential to only use drill bits that are made from high-quality materials. By doing so, you can rest assured that your drilling project will go off without a hitch.

9. Incorrect selection of drill bits

When using a drill, it is important to select the correct drill bit for the job at hand. Incorrectly selecting a drill bit can cause the bit to break, which can lead to serious injury.

In general, it is preferable to use a softer material for drilling into harder materials. For example, when drilling into concrete, you should use a carbide-tipped bit. This type of bit is designed to withstand the high amount of friction generated by drilling into concrete.

Drilling into softer materials such as wood or plastic requires less pressure, and as a result, a standard twist bit can be used. Applying too much pressure when using a twist drill bit may result in the bit breaking and become lodged in the material being drilled.

Always use caution when selecting a drill bit and be sure to follow the manufacturer’s instructions. Doing so will help to ensure that both you and your drill bits stay safe during your next project.

10. Drilling at high speeds

When you are performing high speed drilling, the bits can break due to the centrifugal force. This is caused by the drill bit not being able to grip the material tightly enough.

The harder the material, the more likely it is to break. You can prevent this by using a higher-quality drill bit that is designed for high-speed drilling.

Another way to avoid breaking the drill bits is to use a lower speed setting. This will provide more torque and less chance of breaking the drill bit. If you are drilling through softer materials, you can also increase the speed slightly to help prevent the drill bit from binding.

11. Defects in manufacturing

A crucial part of any manufacturing process is quality control. Even the slightest defects can have a significant impact on the final product. In the case of drill bits, even a small imperfection can lead to breakage during use.

The main types of manufacturing defects are poor dimensional tolerances, bad surface finish, and incorrect heat treatment. Poor dimensional tolerances occur when the dimensions of the drill bit do not meet the specifications. This can happen due to poor equipment, human error, or faulty materials.

A bad surface finish occurs when the surface of the drill bit is not smooth. This can be caused by poor machining or grinding. Incorrect heat treatment can also cause problems.

If the drill bit is not heated to the correct temperature, it can become brittle and break easily. All of these manufacturing defects can lead to drill bits that are less effective and more likely to break.

12. Removing chips poorly

Replacing drill bits is not always as simple as it sounds. In order to remove a drill bit from a chuck, it is necessary to first loosen the chuck. Otherwise, the bit will become stuck and may break if you try to force it out. Once the chuck is loosened, you should be able to remove the bit by hand.

If the bit is still stuck, you may need to use a pair of pliers. Be careful not to grip the bit too tightly, as this could damage the shaft or cause the bit to break. With a little care and patience, it is possible to remove your drill bits without damaging them.

13. A handheld drill Instead of a Pillar Drill

Handheld drills are a versatile and relatively inexpensive tool that can be used for a variety of tasks around the home, from hanging pictures to assembling furniture. When it comes to drilling holes, a handheld drill is not always the best option.

In particular, using a handheld drill to drill through metal can quickly break the drill bit. This is because the force of the drill is not evenly distributed, and the entire weight of the drill is focused on a small area.

The drill bit is subject to a great deal of stress and can quickly snap. In contrast, a pillar drill is specifically designed for drilling through metal. The drill’s weight is evenly distributed across the entire bit, meaning that it can withstand more pressure without breaking. If you need to drill through metal, it is best to use a pillar drill rather than a handheld drill.

14. A Lack of Cooling

When drilling through hard materials, it is important to keep the drill bits cool in order to prevent them from breaking. The heat generated by friction can cause the metal to become brittle and eventually break.

In order to prevent the drill bits from breaking, it is necessary to have a cooling system in place. This can be done with either a coolant or a lubricant.

A coolant helps to remove heat from the metal, while a lubricant helps to reduce friction. By using both a coolant and a lubricant, the risk of breaking drill bits is greatly reduced. If either one of these is not used, the hammer drill bits will eventually break. Therefore, it is essential to have a coolant as well as a lubricant to avoid drill bits breaking.

15. Feed Rates Aren’t Right

As anyone who’s ever worked with a drill knows, getting the feed rate right is crucial. If the feed rate is too slow, the work will take much longer than necessary.

When the feed rate is too fast, then the drill bits will quickly become worn down and in extreme cases, they can even break. This is because the high speed of the drill combined with the friction of the material being drilled can cause the bit to overheat and break.

To avoid this, it’s important to keep an eye on the speed of the drill and adjust accordingly. With a little practice, it’s easy to get a feel for what feed rate is appropriate for each job. And by taking care to avoid breaking drill bits, you can save yourself time and money in the long run.

16. Unsecured Workpiece and Drill

Workpieces and drills that are not secured are common causes of broken drill bits. When a drill bit hits an unsecured object, the impact can cause the tip of the bit to break off. The vibrations from the drill can loosen the connection between the bit and the chuck, causing the bit to fall out and break.

Drill bits can also break if they become misaligned with the workpiece. This can happen if the workpiece is not securely clamped down or if the drill is not held at a 90-degree angle to the surface.

If a drill bit becomes misaligned, it will hit the side of the workpiece and break. To avoid breaking drill bits, always make sure that your workpiece is secure and that your drill is properly aligned before beginning to drill.

FAQs

Do drill bits break easily?

It depends. If you are using a short drill bit, then the answer is probably no. In the case of a long bit, then it is more likely to be yes. This is because the longer the drill bit is, the higher the risk that it will break.

So if you only need to drill into shallow material, then it is advisable to use a short drill bit. If you are drilling into deep material, then you will need to use a long drill bit. Just be aware that longer drill bits are more likely to break.

Why do my drill bits keep going blunt?

If you’ve ever wondered why your drill bits keep going blunt, even after sharpening them, there’s a good chance that you’re just heating them up too much while you’re drilling. When bits get too hot, the metal starts to lose its hardness, and that’s what causes them to go blunt.

Avoid this by using a lower speed setting on your drill and make sure that you’re using plenty of lubricants. If you find that your bits are still getting too hot, try using a larger diameter bit, as this will dissipate heat more effectively. You can do your part by taking some precautions to keep your drill bits in good condition for longer.

What kind of drill bits last the longest?

If you’re looking for drill bits that will last a long time, you’ll want to focus on bits made from high-quality materials. For instance, titanium drill bits are coated with titanium nitride, which is a hard and wear-resistant material. This means that the cutting edges of the drill bit will stay sharp for longer, and the bit will be able to withstand more wear and tear.

The titanium nitride coating also helps to improve the drill bit’s heat resistance, meaning that it won’t overheat as quickly when used for extended periods of time.

Consequently, for drill bits that stand up to heavy-duty use, titanium drill bits are a good option. They do tend to be more expensive than other types of drill bits.

Should I use water when drilling through concrete?

When drilling through concrete, water can be your best friend. The water helps to cool the drill bit, which prevents the concrete from overheating and cracking.

It helps to clear away any dust particles that the drilling process might generate. This can help to prolong the lifespan of your drill bit and make the drilling process easier.

There are a few things to keep in mind when using water for drilling. You need to make sure that the area is well-ventilated. Also, you need to be careful not to overwet the concrete, as this can weaken it and make it more difficult to drill through. With these considerations in mind, using water can be an effective way to drill through concrete.

Last Words

Regardless of why your drill bits keep breaking, it’s important to take a look at how you use your drill and follow best practices. With a little bit of troubleshooting, you should be able to figure out what’s causing your drill bits to break and fix the problem.

If you’re still having trouble, don’t hesitate to reach out to a professional. They can help you figure out what’s going wrong and get your drill bits working properly again. We hope this article has been helpful to you. If so, please share it with your friends and family, who might also find it useful.

Recommended Article To Read: