Lathe machine is one of the important machines used in the manufacturing industry. It is an old tool that uses for shaping and cutting woods and metal. It is a widely used tool, and it is also called the mother of the tool room.

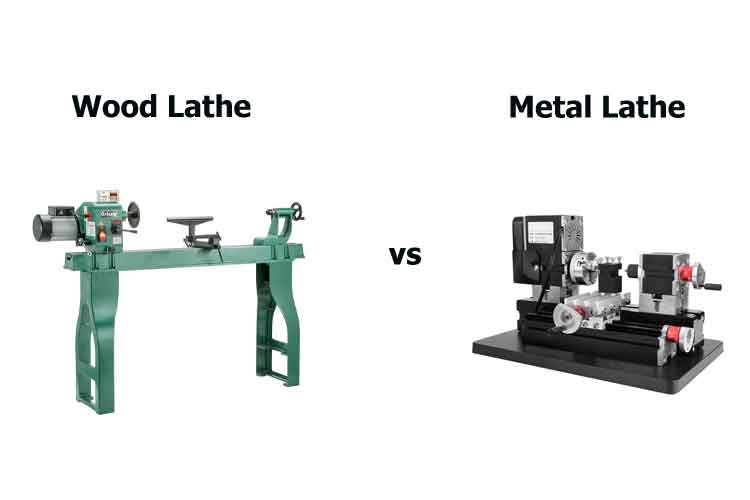

The two common types of lathers are wood lathes and metal lathes. The major difference among these machines is for what purpose these machines are designed. Wood lathe machines are designed for doing the wooden workpiece jobs, while the metal lathe is used for metal workpieces. Wooden lathes machines are comparatively smaller and simpler than metal lathes.

Here we will guide you with some more reliable information to know more about wood Lathe vs metal lathe.

What is a Wood Lathe?

The market is full of plenty of wood lathe tools. Having a wood lathe means getting better shaping and cutting of woods. The cutting process of woods such as sanding, drilling, cutting, and deforming the wooden pieces and cutting the unwanted parts of the woods.

It is said to the oldest type of woodworking in the world of lathe machines. Now there are many modern lathe machines available in the markets that are evolved from the traditional wooden lathe.

In the wood lathe, there is an adaptable horizontal rail that is called the tool rest. The tool rest is the place where the wooden piece is placed. The design and shapes are given to the wood pieces with the use of the operator.

The wood lathe comes in a simple and small size that makes it suitable to place in a smaller space and makes it perfect for performing complex tasks.

There includes a pulley system that helps to regulate the speed to run the lathe. There is no need to mount a wood lathe, it is efficient and effective to work, but it does not provide more power than the metal lathe.

These machines are also do not need to fix you can also use them as a mobile machine that is easy to transport from one place to another. It is pretty easy to perform any of the tasks anywhere and then to use that for hard material to cut the wood and also it is suitable to work with plastic materials.

It comes with a detachable power motor that can use for hard materials, and there is also an option to shift its control to the auto mode by making it a computer-controlled machine.

What are the benefits of Wood lathe?

Let’s take a look at some benefits of having a wood lathe tool.

- It is simple and smaller in size, making it easy to operate and easy to move and place on smaller surfaces.

- Its effective pulley system makes it good to work at high speed and to cut the hardwood materials.

- The wood lathe machine is also suitable to use for light plastic materials

- It is a simple, lightweight, and effective hand tool.

- The wood lathe needs less power and works awesomely with DIY and straightforward projects.

How much does a wood lathe cost?

If you want to get a quality lathe for cutting or sizing wood, you need to spend 600 to 900 dollar on average. If you want more better quality, you need to invest more.

According to the market research, you may need to spend $1000 to $4000 to buy a top-line and high performing wood lathe machine.

However, if you are looking for the best wood lathe for the money or within your budget range, then you can go here to learn more.

A Guide to Metal Lathe

A metal lathe is a modern addition that is perfect to work with all types of hard materials, especially heavy-duty metal projects. It is suitable where you find the wood lathe is not working.

A metal lathe is a powerful machine bigger in size and provides extensive power to make it powerful to cut and shape the hard metal materials. You will find this machine helpful for the functioning of hard metal materials such as aluminum, steel, and iron.

The Metal lathe is widely used in the manufacturing industry to cut and shape hard tools by applying heavy pressure to make metal work easier.

Its cutting tool applies the press against the metal piece, fixed on the metal lathe. It rotates and cuts through the metal in parts. Its spindle is a little bit slow because cutting through the metal and takes time.

But due to its enough power, it becomes hard to use the machine at its high speed because the machine is solid and sturdy, which makes it hard to control the machine at high pressures. To operate that machine, you need an expert to handle its control and to cut the metals.

Its accessories are mechanically controlled tools and stronger motors which makes it heavy. The metal machines are found helpful for military weapons and industrial machinery manufacturing.

What are the advantages of Metal Lathe?

- The metal lathe machine is a powerful cutting tool suitable for hard materials such as steel, iron, and aluminium.

- It is suitable for high-grade military weapons and industrial tools cutting and shaping.

- The machine comes in sturdy style and with special features.

- It provides you with the opportunity to mount for better performance and safety of use.

The main differences: wood Lathe vs metal lathe

- Wood lathe motor installed on the left side and comes in a range of ¾ to 3 HP, while the Metal lathe comes in a range of 1/8 to 3 HP.

- Wood lathe tool set comes with a wide range of adjustment features, But the toolset of metal lathe move at only four positions.

- The wood lathe is cheaper than the metal lathe.

- Metal lathes are stronger, powerful, and suitable for high-grade projects and metal projects, while the wood lathe is suitable for wood projects and smaller and lighter plastic projects.

- A metal lathe is bigger, and you need to mount before working, but a wood lathe is smaller in size and easy to move from one place to another.

Conclusion

Wood lathe and metal lathe are two types of lathe machines widely used for cutting and shaping hard materials. The wood lathe is best for woodworks and also find helpful on plastic projects, but the metal lathe is suitable for all types of hard materials like iron, aluminum, and steel. Both have good features and benefits, but it depends on your nature of the projects to use.